Industry Information

Development status of China's lead-acid battery industry in 2019

1. Overview of the development of the battery industry

The battery manufacturing industry in China is a traditional industry as well as an important part of the new energy industry. It is closely related to multiple strategic emerging industries e.g. new energy vehicles, renewable energy, modern electronic information, new materials, and equipment manufacturing. Battery manufacturing is also the most important basic industry in China's national economic construction, which is related to the national economy and the people's livelihood and the foundation of building a well-off society. Battery products adapt to development of the national economy in China's new situation, safeguard the needs of national defense strategy, and have wide range of applications and play very important role in meeting the diverse needs of the public's work and living consumption. Batteries include physical and chemical batteries. A physical battery is a device that directly converts solar energy, thermal energy, or nuclear energy into DC power using physical effects, such as solar cell, thermoelectric generator, and nuclear battery. A chemical battery is a device that directly converts chemical energy into DC power, such as lead-acid batteries, lithium-ion batteries, zinc-manganese batteries, etc. Among batteries, chemical battery is the most important type. Chemical batteries are classified into primary batteries and secondary batteries according to the ability of recycling. Among them, the primary battery is a battery of active materials that can only be used once, also known as primary batteries, e.g. zinc-manganese batteries, and alkaline manganese batteries; secondary batteries can be rechargeable and recyclable, also known as storage batteries. The storage battery uses the active substance in the battery to output current when a chemical reaction occurs in the discharged state, and a reverse chemical reaction occurs in the charged state to store electrical energy.

2. Lead-acid batteries and environmental protection

equipped with backward production equipment, and unable to be equipped with complete and advanced environmental protection equipment and health protection facilities, which was not conducive to environmental protection and resource utilization. Thirdly, the recycling of lead-acid batteries was completely in an unorganized recycling state, which greatly contributed to lead and acid pollution. Fourthly, a large number of waste batteries flowed to small-scale reclaimed lead plants. Frequent environmental pollution incidents occurred due to out-of-control management. Fifthly, the risk of cadmium pollution existed in power lead-acid batteries. The United States, a global leading producer of lead-acid batteries uses more than 2 million tons of lead annually. However, it has implemented a closed-loop cycle of lead use thanks to its sound regulations and effective measures to control lead pollution, tracking the whole process "from birth to death" including primary lead smelting, battery manufacturing, and recycled lead smelting,. Producers, transporters, operators, product owners and governments at all levels "share their respective responsibilities". Lead pollution in the lead-acid battery industry chain is effectively controlled. With the gradual promulgation and strict implementation of relevant domestic laws and regulations and industry policies and regulations in recent years, the environmental awareness of lead-acid battery companies has gradually improved, the pollution control technologies have continued to be upgraded, and lead pollution by major industry companies has also been effectively prevented and controlled. In particular, after the industry access verification, industry specification conditions verification, and industry environmental protection verification organized by the Ministry of Industry and Information Technology and the Ministry of Environmental Protection, the environmental protection status of industrial enterprises has been significantly improved. Compared with other harmful metals, lead pollution can be controlled and prevented, and lead poisoning can be cured. Certain degree of lead poisoning or excessive blood lead can be reversed and recovered through food therapy and medication adjustment.

3.Industry supply-demand status and reasons for changes

(1)Supply-Demand Status of Global Lead-Acid Battery Market

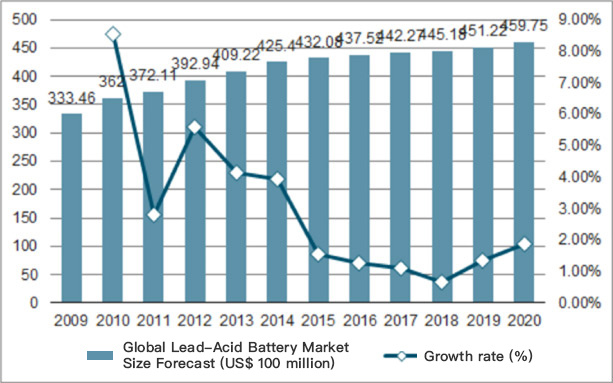

In the global market, lead-acid batteries occupy dominant position in the battery market due to their mature technology, high safety, high recycling efficiency, wide range of applicable temperature, voltage stability, excellent combination consistency, and low price. In 2015, the global lead-acid battery market size accounted for 54.67% of the global battery market size. As battery type with the largest market share in the world, lead-acid batteries are expected to continue to grow globally. In 2015, the global lead-acid battery market size grew by 1.57% over the previous year to reach US$ 43.208 billion. The growth rate is expected to be maintained at 1%~2% in the next 5 years.

Global Lead-Acid Battery Market Size Forecast (US$ 100 million)

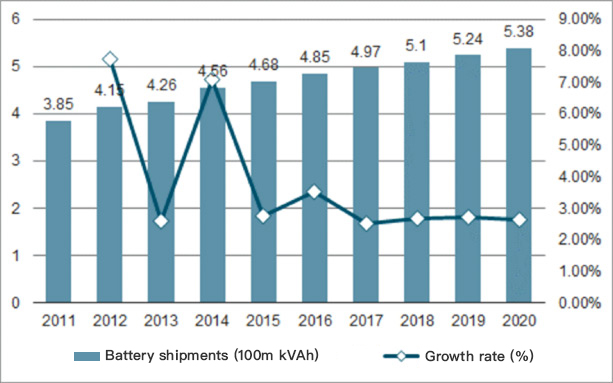

Global lead-acid battery shipments (100m kVAh)

From the perspective of global supply of lead-acid batteries, shipments of lead-acid batteries in 2015 increased by 2.75% over the previous year, reaching 468 million kVAh. The shipments are expected to maintain growth rate of 2%~3% in the next 5 years.

(2)Supply-demand status of lead-acid batteries in China

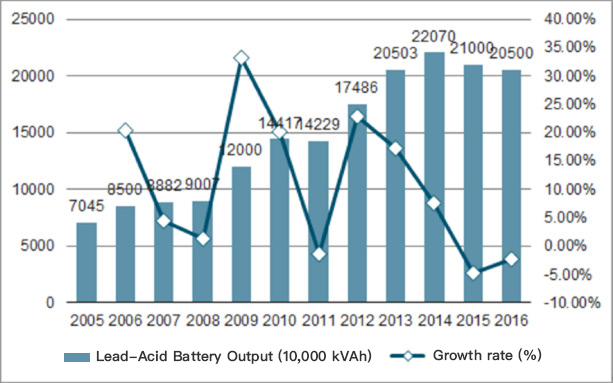

China is the world's largest producer, consumer and exporter of lead-acid batteries. China's lead-acid battery industry mainly implements the strategy of basing production on sales. The number of lead-acid battery production minus the number of exports is roughly the domestic consumption. In the years 2005~2016, the output of lead-acid batteries by domestic enterprises showed volatile growth, with an average annual compound growth rate of 10.17%.

China's Lead-Acid Battery Output, 2005~2016

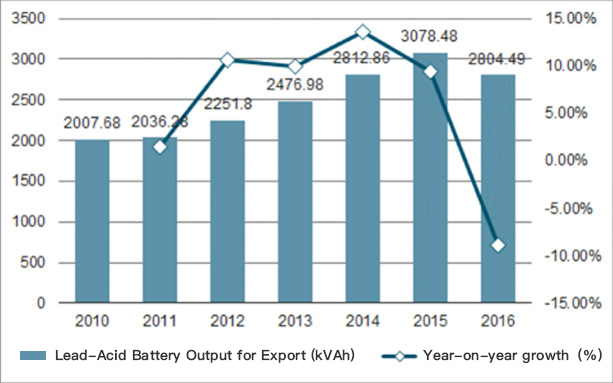

During the 13th Five-Year Plan period, the lead-acid battery output is in expected compound growth rate of 10.76%. By 2020, the output of lead-acid batteries will have reached 350 million kVAh. In recent years, through continuous technology introduction, digestion and absorption of the industry and the investment and construction of factories in China by EU, US, Japan, South Korea and other countries in China, the manufacturing technology of main types of lead-acid batteries in China has approached the international advanced level. Currently, China has become a global leader in the production, consumption and export of lead-acid batteries. In recent years, China ’s export of lead-acid batteries has maintained rapid growth. In 2015, the output of lead-acid batteries was 30.74848 million kVAh, up by 9.44% year-on-year. In 2016, the output of exports dropped to 28.0449 million kVAh, down by 8.90% year-on-year.

China's Lead-Acid Battery Output for Export, 2010~2016

-

About Tysen-Kld

-

PRODUCT

-

APPLICATIONS

-

SERVICE

-

INDUSTRY

-

JOB

-

Copyright: TYSEN-KLD(Beijing) Power Technology Co., Ltd.  Beijing public network security No.11010502040103Edition Beijing ICP No.20004525

Beijing public network security No.11010502040103Edition Beijing ICP No.20004525

Address: Room 606-608, Sixth Floor, No. 651 Yunling East Road, Putuo District, Shanghai Phone: 021-6288-6915